Machine Vision for Industrial Applications

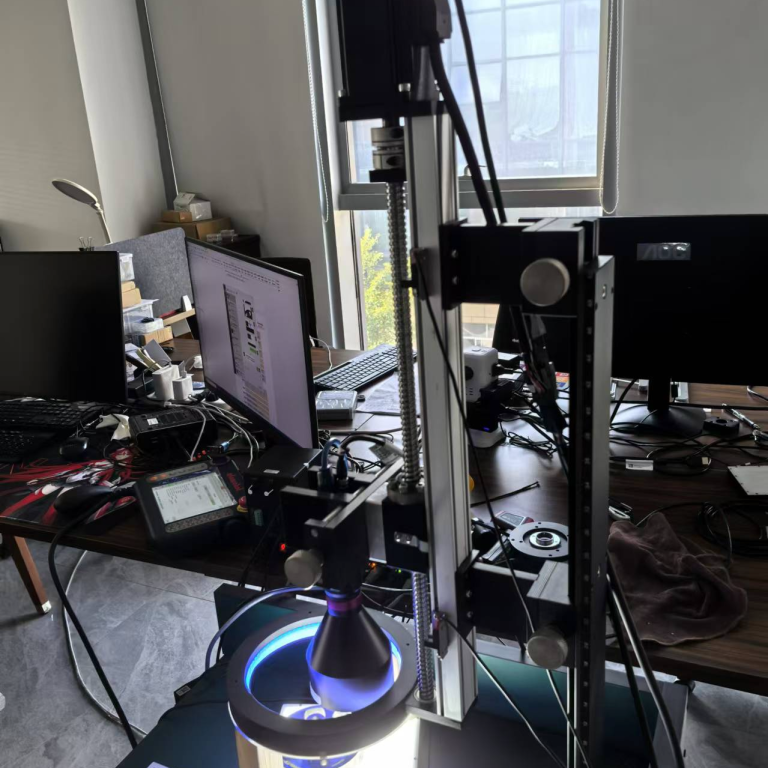

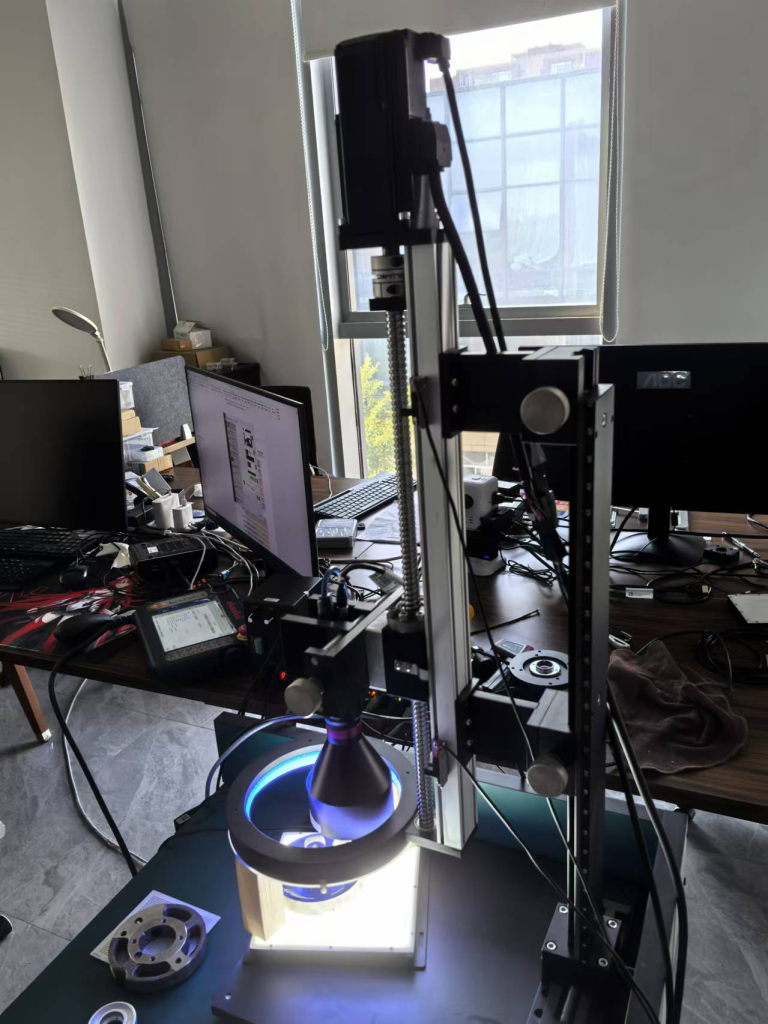

AutonomicVision’s **Autonomic Focusing System** offers versatile machine vision solutions optimized for high-precision inspection, measurement, and automation applications.

- **High-Precision Measurement**: Designed for applications requiring accurate dimensional assessment, the system ensures that all measurements are consistent and reliable.

- **Defect and Abnormality Detection**: Identifies product flaws and irregularities, offering a highly adaptable inspection tool for quality control.

- **Robotic Integration**: Provides adaptable, high-precision imaging to enhance the capabilities of robotic arms, making it an ideal addition for automated sorting, assembly, and inspection tasks.

- **Edge Device and Embedded Systems**: Designed for networked, edge, and embedded environments, making it suitable for a range of device integrations in real-time operations.

Autonomic Focusing System - Technical Overview

Our **Autonomic Focusing System** leverages deep learning algorithms to offer unmatched focus accuracy and consistency. This technology can complete image focusing in any environment, scene, or on any detected product within milliseconds, minimizing downtime and maximizing operational efficiency.

System Integration

- **Networked, Edge Device, and Embedded Compatibility**: Supports various architectures to meet integration needs across industrial automation environments.

- **Cross-Platform SDK**: Compatible with Windows 10/11, Linux Ubuntu 22.04, and all major industrial camera protocols. The system supports C++, Python, and other programming languages, enabling seamless integration into diverse systems and platforms.

- **Adaptive Modeling and Prediction Algorithms**: Tailored algorithms ensure that each autofocus is completed with minimal error, regardless of environmental changes.

Core Architectural Features

- **Multi-Programming Language Compatibility**: Supports C/C++, Python, and other major languages for maximum flexibility.

- **Virtualization**: Compatible with all major industrial camera protocols, allowing easy integration without workflow disruption.

mar

2020

©Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.